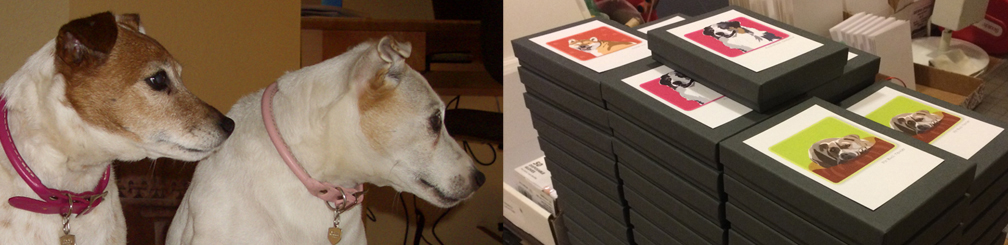

LEFT: Java, Zoe RIGHT: We make 20 boxes per time/design.

OUR STORY Paper Russells' founder and CEO Myunghye [MH] started the company with her two Jack Russell Terriers, Java and Zoe on Nov. 2002 in the San Francisco Bay Area. At the time, they wanted to give a beautiful gift for a dear friend, Jasmine the Poodle, who'd just had a litter of the cutest pups they've ever seen but, couldn't find anything -- not even a card! – anywhere. So, that inspired the three to start Paper Russells, creating eco-friendly stationery and gifts for pet lovers. The company relocated to Ogden, Utah, in 2012, now in Portland, Oregon 2022, in the beautiful Northwest Pacific area.

OUR PHILOSOPHY MADE IN THE USA; The company sources all the material within the USA, e.g., Grrreen boxes from Boston, displays from New Hampshire, and envelopes, frames, cello bags, and paper boxes from California.

SMALL PRODUCTION Paper Russells carries over 1000 products with 500+ original illustrations of pets and animal images. To keep all the products available for every order was a massive challenge in the beginning, yet, we resolved the inventory control issue by working with high-tech digital printing companies. For example, every "Grrreen Box Notes," we make only 20 boxes per design each time – once our local printer sends us the cards, we put them together one box at a time in our studio here in Portland, Oregon by humans.

MORE THAN RECYCLED; For the Grrreen Box Notes and Greeting Cards, we use premium recycled paper that is 100% recycled (PCW), heavyweight (100LB) cover stock, Forest Stewardship Council (FSC) certified. We also manufacture them with 100% renewable green electricity and Processed Chlorine Free (PCF). DogPride and NatureCollection Cards are printed on premium recycled paper that is 30% and 100% PCW content, 80LB cover, and acid-free paper made with electricity offset with certified wind power certificates. FAIR PRICES; Considering our high-quality products using all made in USA material in small quantity production, our prices are quite competitive compared to those mass-produced products with cheap labor and material overseas. We could achieve the goal by lean and efficient processes using cutting edge technology.

|